Boosting Rubber Processing Efficiency with a High-Performance Rubber Mixing Mill

2025-07-29

Rubber manufacturing in the United States is undergoing a silent transformation. As industries demand faster, more accurate, and cost-effective solutions, one machine has quietly become essential to the process: the Rubber Mixing Mill. Whether you're producing rubber sheets, hoses, seals, or industrial tires, investing in a high-quality rubber mixing mill can dramatically improve consistency and output across your production line.

If you're still relying on outdated open mills or manual processing, now might be the perfect time to explore what modern rubber mixing equipment can do for your business.

What Exactly is a Rubber Mixing Mill?

A Rubber Mixing Mill, also known as an open mill, is a core piece of equipment used to mix raw rubber materials with additives like sulfur, carbon black, plasticizers, and colorants. The mill consists of two heavy-duty rollers that rotate toward each other, kneading and shearing the rubber compound to achieve a uniform mixture.

From tire plants to footwear factories, this machine is the heartbeat of any rubber formulation process.

Key Benefits of Upgrading Your Rubber Mixing Equipment

Here are just a few reasons why U.S. manufacturers are replacing legacy machines with advanced mixing mills from China-based suppliers:

1. Precision Mixing for Better Product Quality

Modern mills offer adjustable nip settings, variable speed, and automated temperature control, which allows for consistent dispersion of fillers and additives.

2. High-Efficiency Motor Systems

Energy-efficient motors reduce power consumption while increasing torque, enabling the mill to handle denser compounds without strain.

3. Enhanced Safety Features

Today's machines come with emergency stop bars, roller covers, and interlocking systems—all designed to meet OSHA safety standards.

Honestly, who wouldn't want safer equipment that also runs smoother?

Applications Across Multiple Industries

The versatility of a rubber mixing mill is another huge plus. It supports production in sectors such as:

-

Automotive: Seals, gaskets, vibration dampers

-

Industrial: Conveyor belts, machine feet

-

Construction: Expansion joints, waterproof membranes

-

Consumer: Yoga mats, shoe soles, rubber bands

So whether you're making niche components or mass-market goods, this machine will probably fit the bill.

Why Source Your Mixing Mill from a Chinese Manufacturer?

You might be asking yourself, "Why not buy locally?" Well, here’s the deal:

-

Lower Cost: You get premium quality without the premium price tag

-

OEM & ODM Services: Custom roller diameter, heating method, motor power—tailored to your process

-

Global Logistics: Most suppliers now ship door-to-door to the U.S.

-

Ongoing Support: Remote diagnostics, video setup guides, and spare parts are all part of the deal

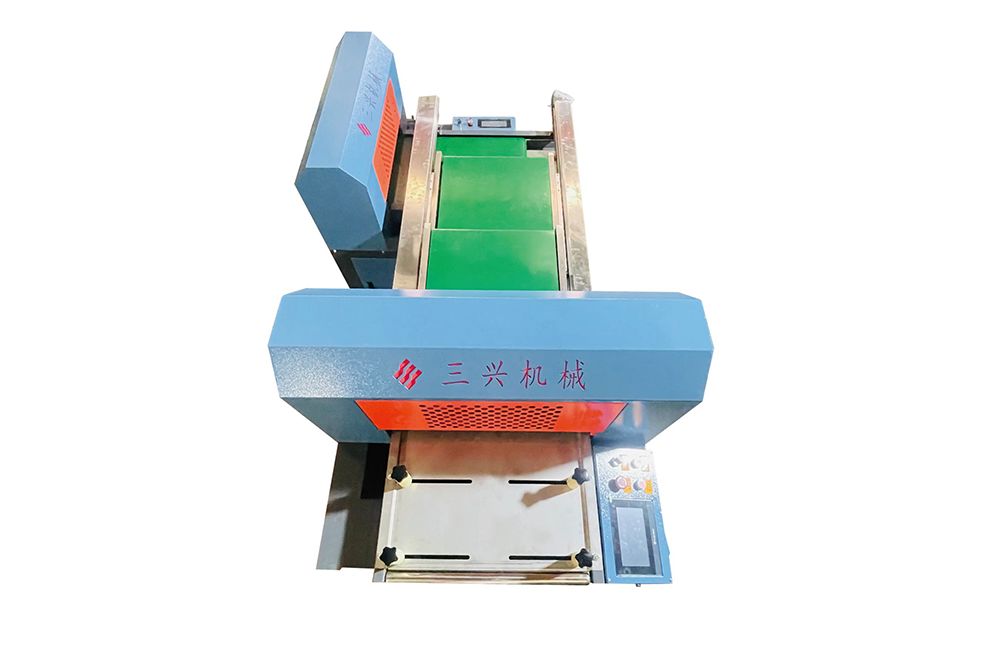

Companies like Quanzhou Sanxing Machinery Industry And Trade Co., Ltd. have been building and exporting rubber machinery since 2011. Their equipment already runs in dozens of factories around the world.

Their machines comes with full testing reports and CE certification to meet international standards.

Choosing the Right Machine Configuration

When shopping for a rubber mixing mill, consider the following specs:

-

Roller diameter and length

-

Roller surface (chilled alloy cast iron preferred)

-

Drive system: electric or steam-heated

-

Control method: manual or PLC-based

Not sure what to choose? No worries. Sanxing’s engineers can guide you through the selection process based on your output needs and rubber formulation.

A Smarter Way to Mix Rubber

Investing in a Rubber Mixing Mill from a Chinese supplier isn’t just a cost-saving move—it’s a smart production strategy. With better control, higher consistency, and global support, U.S. manufacturers can streamline operations and stay ahead of market demands.

If you’re looking for a reliable mixing solution, get in touch with Sanxing Machinery today.